M3D Crane Quad blogResources, Thoughts and Comments about the M3D Crane Quad Printer.

Some helpful links: M3D Quad Owners Facebook Group Youtube video on loading filament into your Quad extruder. Post processing Script by Juan Rosario |

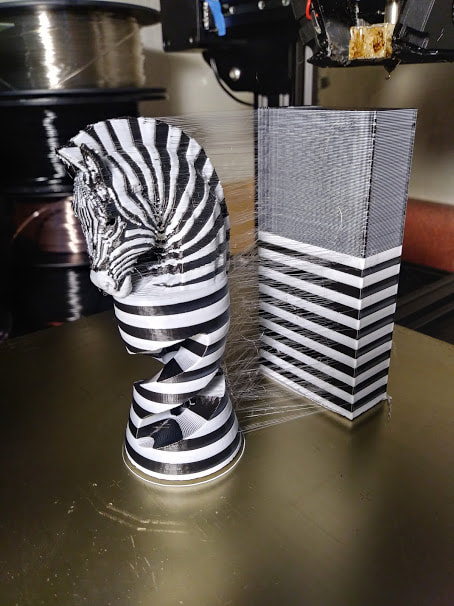

Monochrome printing on the Quad.I have had an electrical issue crop up on my Prusa MK2 and have repair parts on order. In the mean-time I needed to print a series of medium size Knights in CC3D Silk Dark Rose Gold. With limited options, I decided to run these prints on the M3D Quad. To prevent issues with plastic backing up into the nozzle, I loaded the unused ports with PETG filament. I am not 100% convinced this helps but that it a topic for future experiments. Only after starting this, did I realized that monochrome printing is an excellent way to test and tune the performance of this machine and something I should have done weeks ago. On my first print, with the silk PLA I had some issues with under extrusion. I ran a second print in black Hatchbox PLA that came out quite good. So I loaded the silk PLA back into the machine, added a drop of oil to the filament and my next print came out significantly better. I was able to print a series of knights with fairly reasonable quality. I should say that there is a noticeable difference in surface quality of the prints depending on the side of the model. Essentially the side where the filament loads came out shiny and the opposite side came out dark and dull. I assume this has something to do with the asymmetrical extrusion of the filament but it could indicate a difference in the air flow from the parts cooling fans. This difference does not seem to change with temperature or fan levels. (Note I will add a photo that shows the difference between sides) A Knight of Different StripesMy next experiment was to add zebra stripes to the model and attempt to print in black and white. I have been thinking about doing this for a while. It finally occurred to me to create the zebra striping as a separate model and import it into Prusa Slicer edition as a modifier. This proved to be a relatively straight forward process. Prusa Slicer is not set up for the mixing commands with the Duet Board, so I followed up the slice with Sindarius script in this case I simply ran black and white at 100% each. Unfortunately, printing high contrast color changes involves making a big stupid purge tower. I am not a fan of using a bunch of plastic in this way and on this particular model 95% of the purge is only happening in the head of the piece. In addition to the wasted plastic, the non print moves between the piece and the purge tower results in quite a bit of stringing. In the future I intend to look into different means to purge material and I may switch to using the firmware settings for retraction, so I can tune these settings on the fly. What may not be entirely evident in the photos, is there is a some asymmetry in the results on this print. There is significant color bleed on the right side of the model where the left side has nice crisp results. I also managed to accidentally switch the black and white in the process so this zebra has a white nose that was intended to be black.

1 Comment

Addendum to my last post...

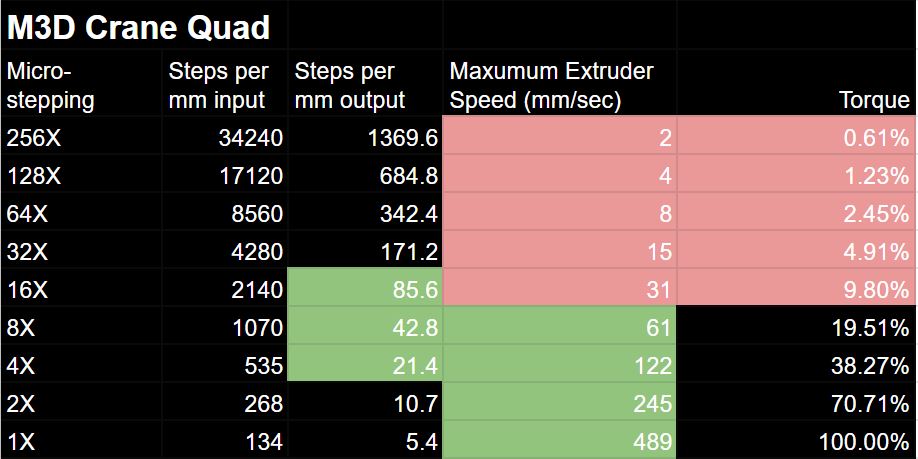

So I tried a quick and dirty test where I marked the filament in 10 mm increments I changed the microstepping levels in motion.g and the step count per mm so that channel 2 and 3 were different, power cycled the machine to set the change and tried extruding and retracting 20mm increments at 60 mm/second. There was no distinguishable difference in speed of movement. But I should also note that the speed of the movement doesn't even approach 60mm per second. I may go back and try shooting high speed video at some point but my guess is it tops out at 15 mm per second. From a retraction standpoint that is a problem. It turns out there is another setting in motion.g that sets the maximum speed of the extruder to 600 mm/minute. Duh! No wonder I am having stringing issues. that is limiting all of the exturders to 10mm per second. No where near what is typically used for retraction moves. So now the test is to see if these motors can handle actually being run at 60 mm/sec on retractions... Fun Fact: Have you ever noticed that the plate in a microwave changes direction almost every other run. This is because the motors have barely enough torque to accelerate the mass of whatever you are cooking. The direction change is intentional and takes advantage of slop in the gear mechanism. When the motor stops turning clockwise the gears are already loaded in that direction. By reversing the motor is able to build up some momentum before the gearing catches up and loads the motor. But how does that have anything to do with 3d Printing or the M3D Crane Quad? Well the answer is fairly technical and my reference to a microwave is abstract at best. To put things in context, I have been trying to sort out issues with extrusion consistency. If you think of the business end of a 3d printer as a fancy hot glue gun, it is extremely important to control the amount of plastic getting pushed through the hot end. Too little extrusion leads to gaps in the print where it can break and too much creates all manner of cosmetic issues like blobs, warts and stringing. Too much extrusion may even result in plastic building up proud of the layer being printed and can catch on the hot end resulting in stringing or worse, horizontal layer shifts. So far my experience with the M3D quad the machine seems to sometimes push too much plastic and other times seems to struggle to push the filament at all. All of the motions on a 3d printer are performed using stepper motors. An oversimplified explanation of a stepper motor is a DC electric motor where the rotation is divided into some number of equal steps. Typically, desktop 3d printers use Nema 17 steppers that have 200 steps (1.8 degrees per step). For the Quad printer, M3D is using their own proprietary motors that are very compact and light. Control over motors utilizes a function called microstepping that allows the motor to smoothly interpolate between these steps. The level of microstepping is expressed in multiples of two (2x, 4x, 8x, 16x, 32x, 64x…) The higher the microstepping the more precise, smoother and quieter the motion. Also, are potentially less resonance as the motors are not stopping only at incremental positions. Doing some research on this I stumbled across an interesting inconsistency in M3D's documentation. The Quad firmware uses a file called motion.g that sets the parameters for how the motors function on the machine. By default the current settings in the Quad printer firmware is set up with 16X microstepping for the extruder motors. However, on their documentation for the quad head when sold as a separate unit M3D recommend using 8X microstepping as a starting point. Intuitively it seems that higher microstepping may result in less torque. That seems to be supported from various sources online. But documentation from Duet (the makers of the control board for the Quad printer) indicate otherwise. None the less I reconfigured my motion.g file to 8x microstepping, re-calibrated and results seem to show much more consistent performance. My rationale is that even at 8x microstepping the Quad motors are running at 1070 microsteps per mm. (The number of microsteps to push 1 mm of filament). While it is debatable how much this actually affects torque, another variable is speed. At lower microstepping, the motors can run at higher speeds. This maximum speed could come into play with retraction settings. Retraction is essentially pulling the filament back away from the hotend, typically to reduce stringing when the printer is making non printing moves. I am not certain but it appears to me that 16x microstepping may limit the speed of the steppers to about 30 mm/sec. Which is about half the speed typically used for retraction. So there is the theoretical background. I have included a table below with some calculators based on the above assumptions. The next step is to devise some tests to determine if microstepping has a measurable impact on consistency, speed and accuracy. Reference Documents: M3D Crane Quad Motion.g M3D Quad Head control recommendations HOW ACCURATE IS MICROSTEPPING REALLY? Choosing and connecting stepper motors (Indicates microstepping does not affect Torque) Microstepping: Myths and Realities (Indicates Microstepping has a negative impact on Torque) WHY 16X MICRO STEPPING IS A BAD IDEA WITH MIXING HOT END (A case for higher microstepping) |

AuthorPlease note I am a user of this product and in no way affiliated with the M3D Company. Your mileage may vary. Archives

January 2020

Categories |

RSS Feed

RSS Feed